Judson History

Judson

Serving the Cleaning Industry Since 1959

It all started one day in 1959 when the family’s wall to wall carpet was cleaned and Judson O. Jones asked, “Where does the dirt Go?”

In the Beginning

It all began with the Deep Clean DC-3 commercial and residential carpet cleaning system.

Over the years Judson Jones, Dick Jones and Les Jones have racked up over 26 U.S. Patents.

These patents are for products and equipment to support cleaning professionals across the country and to assist them in increasing their performance, customer satisfaction, and profits, along with making their job safe, easier and almost effortless.

1959 Deep Clean DC3, manufacturing began with the Portable DC3. Over 60 different models were eventually produced.

1972 – The first Truck Mount was built. It was a direct drive “Big Truck” and had a four foot wide wand that was pulled with a garden tractor. It was designed for Monsanto to clean Astro-Turf fields.

1975 – Judson Products, Judson began manufacturing conventional types of cleaning chemicals and a very unique on-location carpet dyeing system.

1975 – Judson Products, Judson began manufacturing conventional types of cleaning chemicals and a very unique on-location carpet dyeing system.

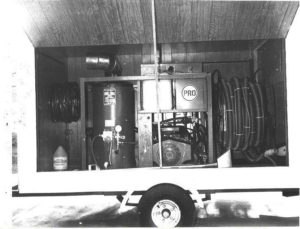

1976 – The Power Pack, a compact self-contained truck mount using Judson trademark design of mounting all the components on top of the recovery tank. 5HP with a #2 blower.

This unit is the first of the Judson trademark design of having all the components mounted on top of the recovery tank. Other firsts for this unit are boat deck plates for recovery tank access and a common water-wall foot valve for a vacuum relief valve.

Some interesting points about this unit, is it only has a 5 HP engine, a #2 blower, and an 85,000 BTU Heater. You would think with this little bit of power that it would not clean carpets very well, but with a 10 inch wand with .04 jetting it would run 300 feet of hose. Not as fast as your current day machines, but it would collect the money from the customer.

1977 – The Nitro, a mid sized truck mount for smaller vehicles. 18 HP with #33 blower.

1978 – The Dynamite, a stainless steel upholstery and drapery cleaning machine that could pump solvents.

1978 – Judson Private Labeling began on truck mount systems and Judson Products.

1979 – The X-15. A portable one piece stainless stell body and tank combination that eliminated cracks and leaks typical of portables.

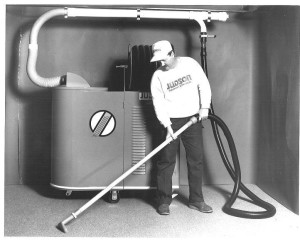

1980 – The Turbo Vac industrial vacuum cleaners. World’s largest portable electric vacuum. 20 HP with #47 blower.

1981 – Power Converter. A portable device to convert 2 – 110 volt circuits into 220 volts in order to operate our powerful portables.

1982 – The Rextar Stainless Steel Portable. High heat, high vacuum, high pressure, auto-fill and auto-pump out.

1982 – Nitro/GE & TNT/GE. GE stood for Gas & Electric. We added an electric motor to the standard Nitro and TNT. The Nitro had drop down legs so one man could load and unload it from a van for indoor electric powered cleaning.

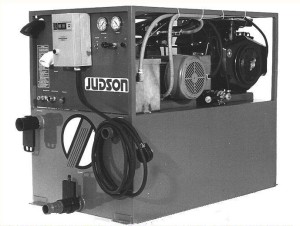

TNT/GE

This is the 1982 Judson TNT-GE, which stood for Gas-Electric. Again, this unit uses the Judson trademark of mounting the components on top of the recovery tank. At this time, the truck mount market had not broken the $10,000 barrier and at a price of $15,000 we only sold approximately 400 machines. The units that we did sell worked extremely well. Having 2 power sources made it very unique (a gasoline engine and an electric motor). Whebn using this unit for commercial work, you would use the 220 volt electric motor. Dropping the operating cost down aand keeping the time off the gas engine. Also, having 2 power sources was a good backup system if one failed. The unit was designed for mini-vans and could be slid out on its wheels and taken in doors and plugged in to a standard 110 volt outlet.

1984 – Industrial Centralized Zone Vacuum Systems. Tight places could be accesed and vacuumed easily with the power of a single Turbo Vac in multiple zones using a permanent pipe system throughout an industrial plant.

1996 – The Aero Vac. A gas powered industrial vacuum cleaner safe enough to be pulled on the tarmac next to aircraft in order to do maintenance and housekeeping chores.

1997 – Postal Equipment Vacuum Systems Vacuum equipment designed for maintenance and housekeeping of ultra-high postal sorting equilpment.

1998 – Draft inducted LP Heat Exchange System. An ultra-high efficiency heat exchange system that can be used in many industries.

2002 – Homeland Security Vacuum Separator. An in-line separator to capture and destroy dangerous poisons and toxic materials.

2005 – Advanced, High-Powered, High Value Chemicals.

An entire new class of chemical manufacturing using only American-made raw materials of a premium quality in a maximum state of concentration. No extra water. Todayy there are six exceptional products that work extremely well, saving the professional cleaner or consumer time, energy, and money. This is achieved by the products’ speed and efectiveness, the fair purchase price and the savings from not paying to ship water.

Environmentally-Friendly Products

2006 – The Lazer. The first zero problem heat exchange truck mount. Only one metal non-moving part on the entire system.

2007 – The Reactor – The world’s best slide-in truck mount.

100% Satisfaction Guaranteed Seal

All Judson Products Endorsed by National Cleaning Policy Institute

Judson

5 Ellendale Drive

Greenville, SC 29609

SC 864-233-6442

FL 941-724-0701